Pyranometer

A pyranometer is a type of actinometer used for measuring solar irradiance on a planar surface and it is designed to measure the solar radiation flux density (W/m2) from the hemisphere above within a wavelength range 0.3 μm to 3 μm. The name pyranometer stems from the Greek words πῦρ (pyr), meaning “fire”, and ἄνω (ano), meaning “above, sky”.

A typical pyranometer does not require any power to operate. However, recent technical development includes use of electronics in pyranometers, which do require (low) external power.

Explanation

The solar radiation spectrum that reaches earth’s surface extends its wavelength approximately from 300 nm to 2800 nm. Depending on the type of pyranometer used, irradiance measurements with different degrees of spectral sensitivity will be obtained.

To make a measurement of irradiance, it is required by definition that the response to “beam” radiation varies with the cosine of the angle of incidence. This ensures a full response when the solar radiation hits the sensor perpendicularly (normal to the surface, sun at zenith, 0° angle of incidence), zero response when the sun is at the horizon (90° angle of incidence, 90° zenith angle), and 0.5 at a 60° angle of incidence. It follows that a pyranometer should have a so-called “directional response” or “cosine response” that is as close as possible to the ideal cosine characteristic.

Classification of pyranometers

Following the classifications and definitions noted in the ISO 9060,[1] three types of pyranometers can be recognized and grouped in two different technologies: thermopile technology and silicon semiconductor technology.

The light sensitivity, known as ‘spectral response’, depends on the type of pyranometer. The figure to the right shows the spectral responses of the three types of pyranometer in relation to the Solar Radiation Spectrum. The Solar Radiation Spectrum represents the spectrum of sunlight that reaches the Earth’s surface at sea level, at midday with A.M. (air mass) = 1.5.

The latitude and altitude influence this spectrum. The spectrum is influenced also by aerosol and pollution.

Thermopile pyranometers

A thermopile pyranometer is a sensor based on thermopiles designed to measure the broadband of the solar radiation flux density from a 180° field of view angle. A thermopile pyranometer thus usually measures 300 to 2800 nm with a largely flat spectral sensitivity (see the Spectral Response graph) The first generation of thermopile pyranometers had the active part of the sensor equally divided in black and white sectors. Irradiation was calculated from the differential measure between the temperature of the black sectors, exposed to the sun, and the temperature of the white sectors, sectors not exposed to the sun or better said in the shades.

In all thermopile technology, irradiation is proportional to the difference between the temperature of the sun exposed area and the temperature of the shadow area.

Design

In order to attain the proper directional and spectral characteristics, a thermopile pyranometer is constructed with the following main components:

- A thermopile sensor with a black coating. It absorbs all solar radiation, has a flat spectrum covering the 300 to 50,000 nanometer range, and has a near-perfect cosine response.

- A glass dome. It limits the spectral response from 300 to 2,800 nanometers (cutting off the part above 2,800 nm), while preserving the 180° field of view. It also shields the thermopile sensor from convection. For first class and secondary standard pyranometers (see ISO 9060 classification of thermopile pyranometers) a second glass dome is used. This construction provides an additional “radiation shield”, resulting in a better thermal equilibrium between the sensor and inner dome, compared to using a single dome. The effect of having a second dome is a strong reduction of instrument offsets.

In the modern thermopile pyranometers the active (hot) junctions of the thermopile are located beneath the black coating surface and are heated by the radiation absorbed from the black coating.[2] The passive (cold) junctions of the thermopile are fully protected from solar radiation and in thermal contact with the pyranometer housing, which serves as a heat-sink. This prevents any alteration from yellowing or decay when measuring the temperature in the shade, thus impairing the measure of the solar irradiance.

The thermopile generates a small voltage in proportion to the temperature difference between the black coating surface and the instrument housing. This is of the order of 10 µ • VW/m2. Typically, on a sunny day the output is around 10 mV. Each pyranometer has a unique sensitivity, unless otherwise equipped with electronics for signal calibration.

Usage

Thermopile pyranometers are frequently used in meteorology, climatology, climate change research, building engineering physics and in photovoltaic systems.

They are usually installed horizontally in meteorological stations and typically mounted in the ‘plane of array’ (with the sensor surface parallel to the solar panel) when used for monitoring of photovoltaic systems.

The solar energy industry, in a new standard, IEC 61724-1:2017, has defined what type of pyranometers should be used depending on the size and category of solar power plant.

Photodiode-based pyranometer

Also known as a silicon pyranometer in the ISO 9060,[3] a photodiode-based pyranometer can detect the portion of the solar spectrum between 400 nm and 900 nm, with the most performant detecting between 350 nm and 1100 nm. The photodiode converts the aforementioned solar spectrum frequencies into current at high speed, thanks to the photoelectric effect. The conversion is influenced by the temperature with a raise in current produced by the raise in temperature (about 0,1% • °C)

Design

A photodiode-based pyranometer is composed by a housing dome, a photodiode, and a diffuser or optical filters. The photodiode has a small surface area and acts as a sensor. The current generated by the photodiode is proportional to irradiance; an output circuit, such as a transimpedance amplifier, generates a voltage directly proportional to the photocurrent. The output is usually on the order of millivolts, the same order of magnitude of thermopile-type pyranometers.

Usage

Photodiode-based pyranometers are implemented where the quantity of irradiation of the visible solar spectrum, or of certain portions such as UV, PAR, or IR, needs to be calculated. This is done by using diodes with specific spectral responses. Photodiode-based pyranometers are the core of luxmeter used in photography, cinema and lighting technique. Sometimes they are also installed close to modules of photovoltaic systems.

Photovoltaic pyranometer

Built around the 2000s concurrently with the spread of photovoltaic systems, the photovoltaic pyranometer is a derivation of the photodiode pyranometer. It answered the need for a single reference photovoltaic cell when measuring the power of cell and photovoltaic modules.[4] Specifically, each cell and module is tested through flash tests by their respective manufacturers, and thermopile pyranometers do not possess the adequate speed of response nor the same spectral response of a cell. This would create obvious mismatch when measuring power, which would need to be quantified.[5][6] In the technical documents, this pyranometer is also known as “reference PV cell”, “irradiance sensor”, “solarimeter”, “solar sensor”, as bibliographies are more recent than the ISO 9060.

The active part of the sensor is composed of a photovoltaic cell working in near short-circuit condition. As such, the generated current is directly proportionate to the solar radiation hitting the cell in a range between 350 nm and 1150 nm. When invested by a luminous radiation in the mentioned range, it produces current as a consequence of the photovoltaic effect. Its sensitivity is not flat, but it is same as that of Silicon photovoltaic cell. See the Spectral Response graph.

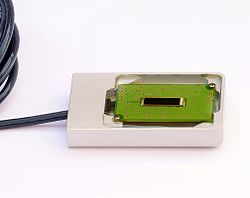

Design

A photovoltaic pyranometer is essentially assembled with the following parts:

- A metallic container with a fixing staff

- A small photovoltaic cell

- Signal conditioning electronics

Silicon sensors such as the photodiode and the photovoltaic cell vary the output in function of temperature. In the more recent models, the electronics compensate the signal with the temperature, therefore removing the influence of temperature out of the values of solar irradiance. Inside several models, the case houses a board for the amplification and conditioning of the signal.

Usage

Photovoltaic pyranometers are used in solar simulators and alongside photovoltaic system for the calcula

Standardization and calibration

Both thermopile-type and photovoltaic pyranometers are manufactured according to standards.

Thermopile pyranometers

Thermopile Pyranometers follow the ISO 9060 standard, which is also adopted by the World Meteorological Organization (WMO). This standard discriminates three classes. Rather confusingly, the best is confusingly called “secondary standard” (i.e., calibrated by direct comparison with the single primary instrument). The second best is defined as “first class” and the last one “second class”.[7] Differences in classes are due to a certain number of properties in the sensors: response time, thermal offsets, temperature dependence, directional error, non-stability, non-linearity, spectral selectivity and tilt response. These are all defined in ISO 9060. For a sensor to be classified in a certain category, it needs to fulfill all the minimum requirements for these properties.

The calibration is typically done having the World Radiometric Reference (WRR) as absolute reference. This is maintained by PMOD in Davos, Switzerland.[8] In addition to the World Radiometric Reference there are private laboratories such as ISO-Cal North America who have acquired accreditation for these unique calibrations. For the “secondary standard” pyranometer, calibration is done following ASTM G167, ISO 9847 or ISO 9846.[9] First and second class pyranometers are usually calibrated according to ASTM E824, and ISO 9847.

Photovoltaic pyranometers

Photovoltaic pyranometers are standardized and calibrated under IEC 60904-4 for primary reference samples and under IEC 60904-2 for secondary reference samples and the instruments intended for sale.

In both standards, their respective traceability chain starts with the primary standard known as the Group of Cavity Radiometer by the World Radiometric Reference (WRR).[10]

Signal conditioning

The natural output value of these pyranometers do not usually exceed tens of millivolt (mV). It is considered a ‘weak’ signal, and as such, rather vulnerable to electromagnetic interferences, especially where the cable runs across decametrical distances or lies in photovoltaic systems. Thus, these sensors are frequently equipped with signal conditioning electronics, which allows them to amplify its natural output value by 100 or 1000 times.

Another solution implies greater immunities to noises, like a 4-20 mA current loop or Modbus over RS-485 output, suitable for ambiances with electromagnetic interferences typical of medium-large scale photovoltaic power stations. The equipped electronics often concur to normalize the signal output into a predetermined value and easy integration in the system’s SCADA.

Additionally, information on the sensor can be stored in the electronics of the sensor, like calibration history, serial number. Some pyranometers also offer extra information like case temperature and sensor tilt angle.

See also

- Actinometer

- Photodiode

- Heat flux sensor

- Net radiometer

- Pyrgeometer

- Pyrheliometer

- Radiometer

- Sunlight

- Solar constant

- Sun path

References

- ISO9060 :1990 Classification of Pyranometers

- http://www.kippzonen.com/News/572/The-Working-Principle-of-a-Thermopile-Pyranometer#

- ISO9060 – Paragraph 3.4 (1990)

- IEC 60904-4:Procedures for establishing calibration traceability

- EN 60904-2: Requirements for reference solar devices

- EN 60904-7: Computation of spectral mismatch correction

- “ISO 9060:1990 Classification of Pyranometers”.

- “World Radiometric Reference”.

- ISO 9846:1993 -Calibration of a Pyranometer Using a Pyrheliometer

IEC 60904-4:Procedures for establishing calibration traceability- Table1 and Fig.1